Fluoride Removal Systems

System Features

- Will treat fluorides from any source

- No limit to the amount of fluorides that can be removed

- Can treat to a limit as low as 2 mg/L total fluoride

- Batch Systems as small as 50 GPD

- Continuous Systems as large as 2,000 GPM

- Can use either Lime or Calcium chloride for Calcium source

- Fully Automated, operator intervention required for maintenance and inspections only.

Fluorides, while not necessarily an EPA priority pollutant, are still

regulated with limits as low as 2 mg/L

showing up in some locations while a limit of 17 mg/L is more common.

Digital Analysis manufactures a complete line of fully automated fluoride reduction

systems for the removal of fluorides from industrial wastewater.

Fluoride removal system sizes ranging from 50 GPD to over 1,000 GPM.

Do you have an application? If so then contact at us via the phone number or email address at the bottom of this page and allow our application engineers assist you. We take complete responsibility for the design and the performance of any wastewater treatment system that we build. We will also perform a complete treatability study with client supplied samples with which we will confirm proposed treatment efficacy, chemical usage, sludge generation volumes, and cost of operation.

(View from filter press)

Optional Equipment

- SCADA System Monitoring

- Remote Monitoring via an Internet Connection

- Paging of alarms via email, cell phone, or SMS Text

- Influent / Effluent Lift Stations

- Final Effluent Monitoring

- Effluent Sampling

- Duplex Systems for Redundancy

- Bulk Chemical Delivery

- Explosion Proof Design

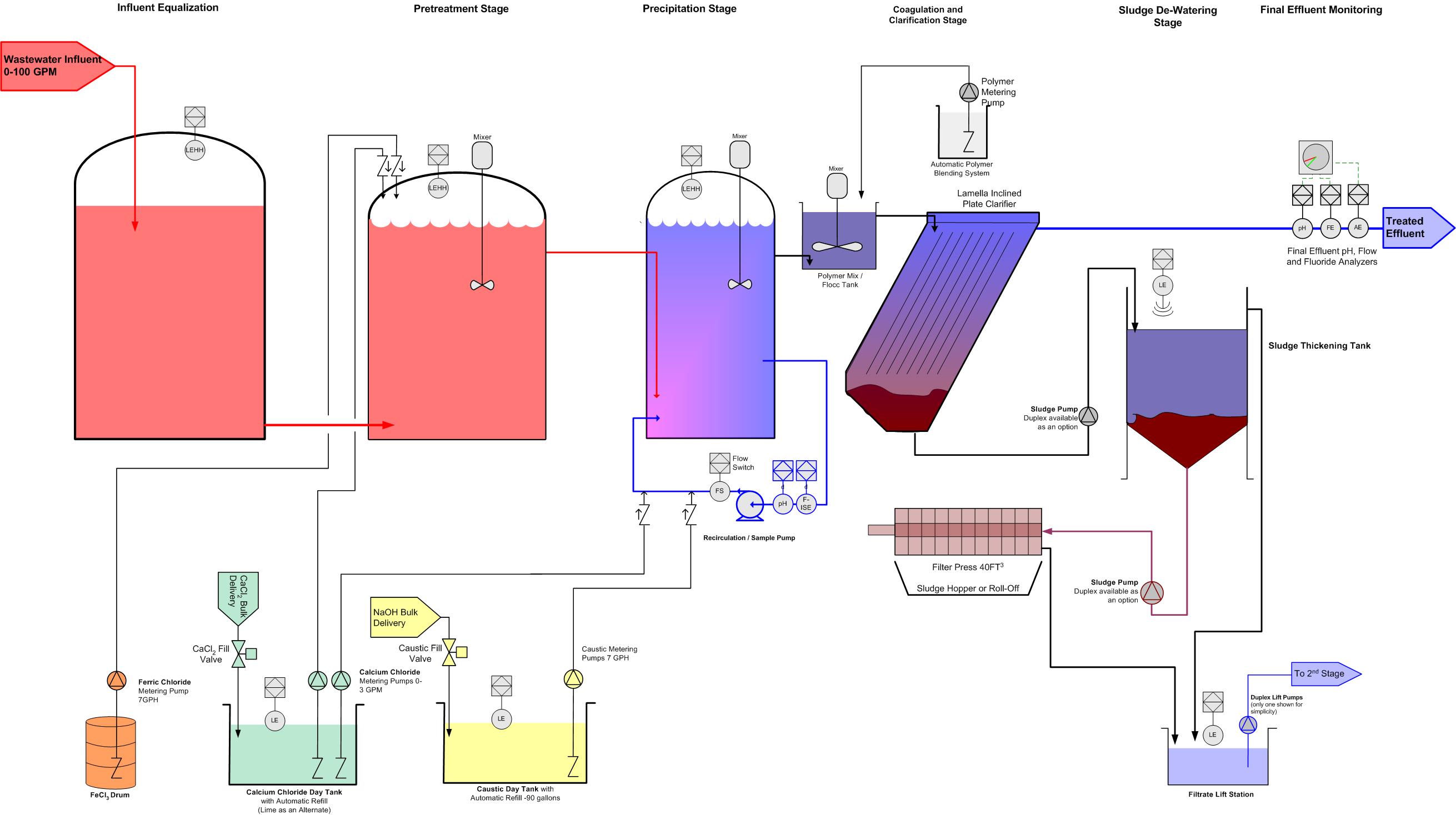

Digital Analysis manufactures both batch and continuous flow through systems. A batch system is more well suited for low or intermittent flows and / or high influent fluoride loading (e.g. > 10,000 mg/L) while continuous flow systems are more well suited for higher flows and lower influent concentrations. In the example above the entire treatment process including pretreatment, precipitation, coagulation, and gravity separation all occur in a single multi-step batch reactor. The example shown below is a continuous flow system.

If your application requires the pH neutralization of hydrofluoric acid (HF) or the removal of fluorides please contact us or see our technical article on fluoride reduction or various case studies.