Boiler Blowdown pH Neutralization Systems

- Skid Mounted

- Turnkey Construction

- Minimal Installation Time

- Completely Automated

- NEMA 4X, UL 508

- State of the Art Controls

- Bi-Directional pH Control.

- High Temperature Design with process cooling.

Boiler chemistry is critical to maintaining both the life and

efficiency of boiler operations. As water is lost through

evaporation and condensation total dissolved

solids concentration (TDS) is driven upward resulting in

increasing alkalinity from carbonates and treatment chemicals.

The result is continuously changing chemistry and increasing pH of a body of water that is already quite alkaline. To maintain an effective chemistry boilers periodically blowdown a small volume of water that will be high in TDS and possibly TSS as well. The pH of this blowdown is typically far too high to discharge to the public sewer system / POTWs requiring pH neutralization prior to discharge.

All four of our pH neutralization families - pHASE, labTREAT, batchTREAT, and hydroTREAT are well suited for the neutralization of boiler blowdown wastewater.

Since the boiler will blow down at a very high temperature, usually well in excess of 2120F, the boiler will blowdown to a flash tank prior to the neutralization system where the water flashes to steam and then has an opportunity to condense. The result is very hot wastewater that must be cooled and neutralized. The diagram below illustrates a typical configuration.

The chemistry of boiler blowdown pH neutralization is fairly simple in that the

wastewater parameters do not change significantly.

However, TDS, TSS, and temperature all may be high and all of these parameters must be carefully considered in the proper selection and design of a system.

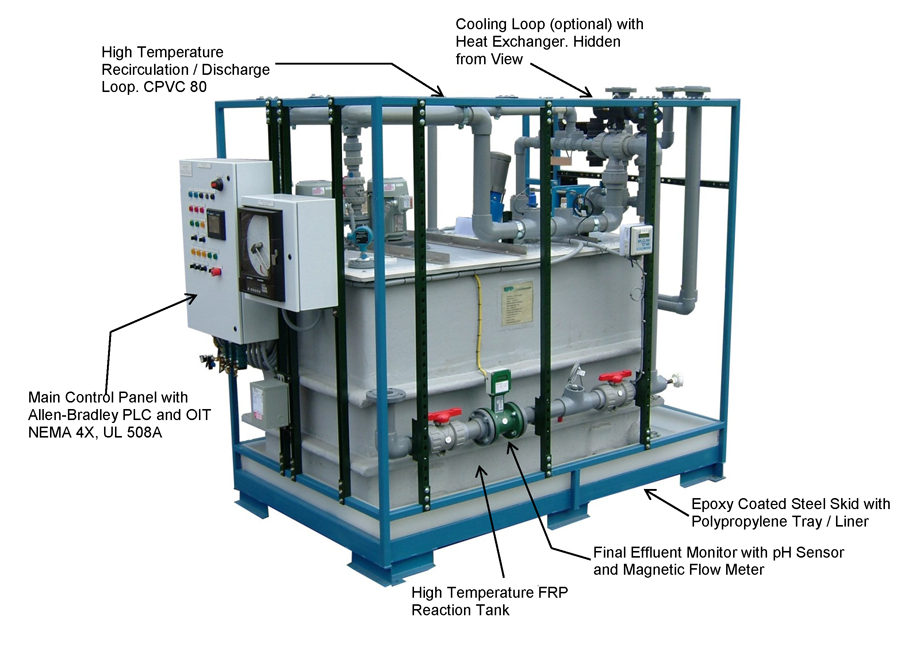

The system depicted below is a high temperature batch neutralization system designed to process in excess of 1200 gallons per hour of hot boiler blowdown.

In a typical scenario we will process no less than four 300 gallon batches / hour from the upstream equalization or flash tank.

Contact us today with your application information and let one of our application engineers make a selection for you.

For the specifying engineer allow us to help you specify a system with sample specifications

and drawings including Process and Instrument Diagrams (P&ID) and General Arrangement

(Iso, Plan, and Elevation).