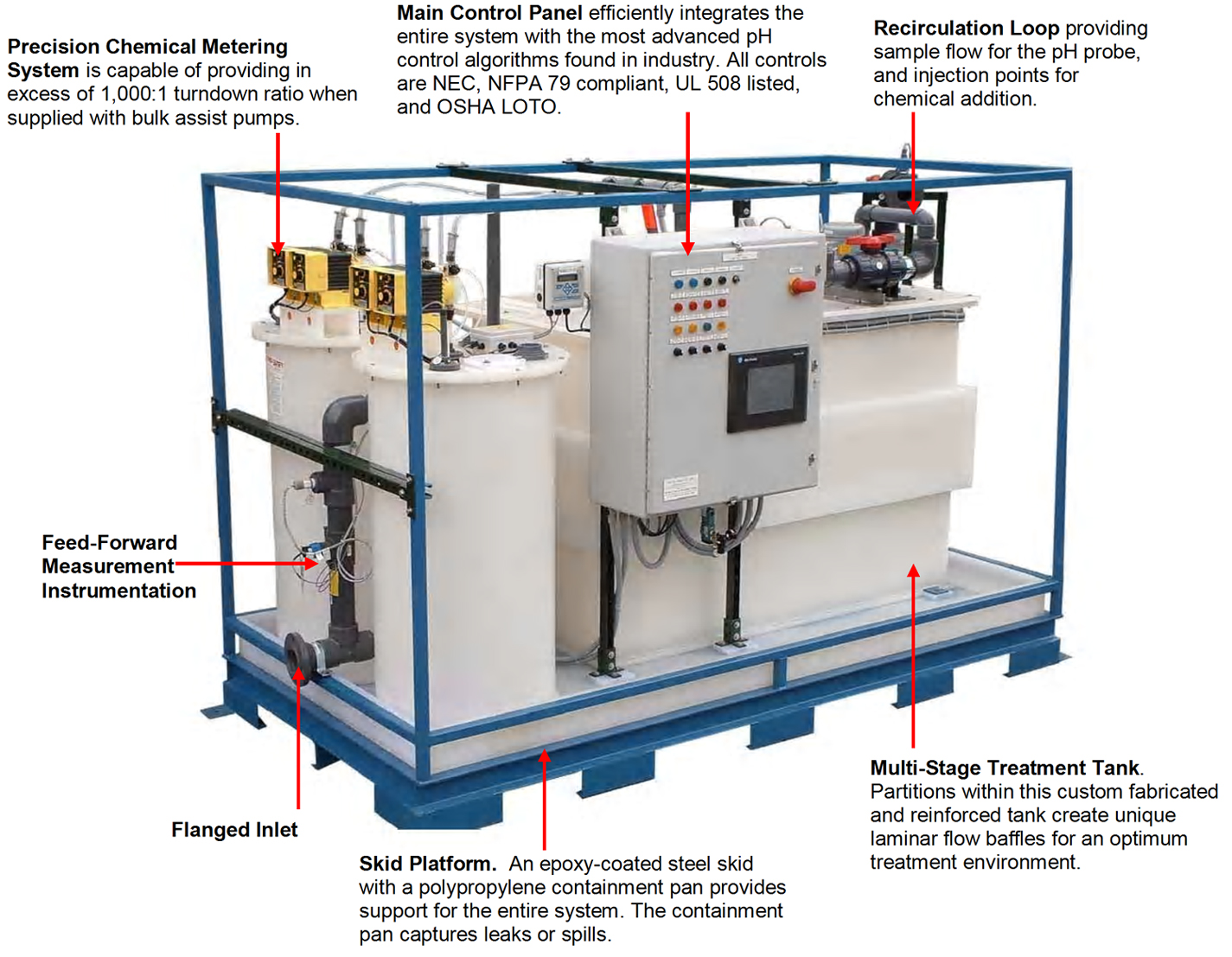

labTREAT LT25 25 GPM Lab Wastewater pH Neutralization System

System Performance Specifications:

The labTREAT LT25 is capable of treating wastewater flows up to 25 GPM continuous and 70 GPM intermittent. With the use of an influent equalization system, which is standard on all of our neutralization systems, periodic flows in excess of 100 GPM can be handled.

The labTREAT family of pH systems are well suited to neutralize wastewater streams from any source including pharmaceutical manufacturing, CIP wastes, university laboratories, and science labs.

Effluent pH Range: typical 6.5 < pH < 8.5 (note: the effluent pH range is fully programmable through the operator interface).

Effluent Monitoring: As mandated by the local controlling authority and by most discharge permits continuous monitoring of effluent flow and pH is provided on a circular chart recorder, paperless recorder, or via a data logger. Additionally SCADA systems are available with automatic report generation.

Controls: All of our pH Adjustment Systems are fully automated with PLC based controls (typically Allen-Bradley) with no operator intervention required.

Utilities, Weights, Dimensions:

The Main Control Panel (MCP) is equipped with an optional main disconnect providing OSHA Lock Out / Tag Out (LOTO) and UL 508 compliance. Electrical requires a single point connection.

All of our pH adjustment systems utilize a fail safe valve on the discharge that immediately halts flow in the event of a discharge contravention, alarm, or a loss of power. This valve requires a small air supply. If air is not available the same function is provided in an all electric configuration.

Electrical: 480VAC, 3 phase, 60 Hz, 15 amp. Disconnect not required (a disconnect is provided on our MCP).

Air: Less than 1 SCFH @ 80 psig.

Dimensions: 48" x 60" x 108"(H) - Not Including the optional influent equalization system.

Weight: Approx. 850 lbs. dry (not including shipping crate).

Construction:

All systems undergo an extensive documented Factory Acceptance Test (FAT) with GAMP validation available.

Pipe, Valves, and Fittings: PVC, CPVC, PP, PE, PVDF, and all stainless alloys.

Main Control Panel: All of our pH systems are controlled by an programmable logic controller (PLC) typically Allen-Bradley. All panels are built to NEC, UL 508 and OSHA standards.

Weight: Approx. 9000 lbs. wet / in use.

Note labTREAT®is a registered trademark of Digital Analysis Corp.